Raw materials

Elastomer, polyurethane, polyamide and plastic gasket seals from Dijon

The materials we use are available with different hardness ratings according to your requirements. We have the necessary certifications to ensure compliance with food standards (FDA), pharmaceutical standards (USP), etc.

For more information on the characteristics of the materials used, please contact us. The

experts at Fastring will be happy to advise and guide you.

Our references

Raw materials used to optimise your projects

Nitrile rubber (NBR)

This is a rubber with a wide range of applications. The higher the percentage of ACN (acrylonitrile) in the composition, the more resistant NBR is to mineral oils and fuels.

Polyurethane (PUr)

The preferred solution for many hydraulic applications, polyurethane has the advantage of high mechanical resistance to wear and oil.

Butyl

This rubber offers a very low permeability to gases such as air and steam. It is also flexible and has good weather resistance.

Silicone (MVQ red, white, translucent)

This type of silicone is mainly used in the food and medical industries. Silicone rubber provides one of the best heat resistance ranges available.

Viton (FPM), perfluoroelastomer (FFKM)

Mainly used in industrial sealing applications for its chemical and thermal resistance.

Virgin polytetrafluoroethylene (PTFE), modified PTFE, filled PTFE

A thermoplastic that is particularly resistant to chemical decay, this polymer is widely used in high-tech industries such as aeronautics and aerospace.

EPDM rubbers

With a very good resistance to climatic stresses, these rubbers offer good mechanical characteristics. An ideal material for hot water and brake fluid applications.

Polyamide

This material is resistant to most hydrocarbons, alkalis and organic chemicals. It can be used at a wide range of temperatures, too.

Delrin

Polyoxymethylene (POM) has very good mechanical properties, high tensile strength and impact resistance as well as excellent wear resistance properties. The mechanical engineering, automotive, textile and food industries use this quality material.

Paper, foam or PVC

Far from exhausting a material, we should only take its flower.

Jean de La Fontaine

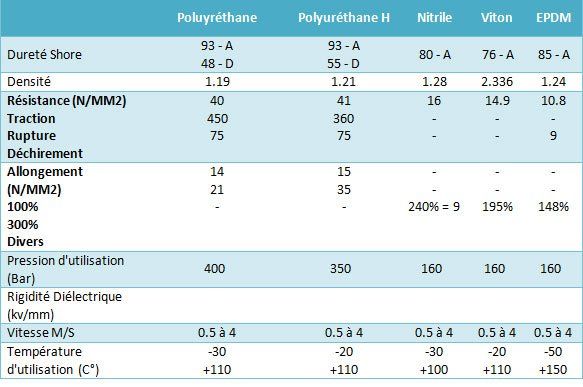

Material characteristics